What is Six Sigma DMAIC

The power of Six Sigma DMAIC Framework

Six Sigma DMAIC is a popular and famous process improvement framework. DMAIC stands for Define, Measure, Analyze, Improve and Control.

This is a very robust and result oriented framework that helps to improve any process whether in business or life.

What is Six Sigma

Before getting into the Six Sigma DMAIC, lets first understand what Six Sigma is all about.

Why not 7, 8, 9 or 10 sigmas. Why only 6 Sigma. Let’s first understand what this concept is all about.

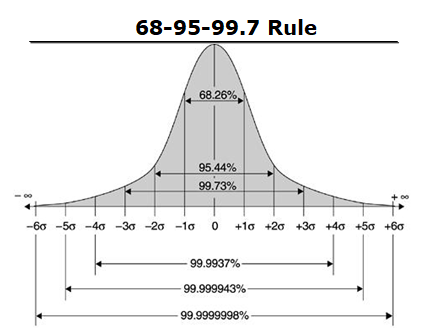

Six Sigma basically is a statistical term. Sigma in statistics is also called standard deviation.

And standard deviation in statistics means how far are the data points from the mean (average).

In business terms, you can say how much is the variation in the process output from the mean point.

As an example, if the average (mean time) of delivering the pizza is 30 minutes, and standard deviation is 10 minutes that means that many deliveries may fall out of 30 minutes. It may be 40 minutes or more.

The concept of 6 Sigma is that when we chart the pizza delivery data on a graph, we draw a perpendicular line in the middle to show the mean of 30 minutes. Then you can make the 6 intervals with 6 standard deviations from the mean of 30 Minutes on right side i.e. 40 minutes, 50 minutes, 60 minutes, 70, minutes, 80 minutes and 90 minutes.

When you plot all the data on the graph, you will come to know that how much deliveries were within the 30 minutes, how much within 40 minutes, and how much within 50 minutes and so on.

This will give you the complete data points showing the mean and the standard deviation.

Six Sigma Process Level (Z Score)

In order to determine the six sigma process level (aka Z Score), it is important to obtain the customer specifications or desired delivery time requirements. For example, customers want their pizza delivered in 40 minutes’ time (maximum). That means that anything delivered later than 30 minutes is a defect for the company.

This also means that Six Sigma means defect-less process. And that means all the deliveries should be within 40 minutes, so all the data should be within the first interval distance of 10 minutes’ standard deviation. If it is not, then certainly it is not a Six Sigma process.

Now if you imagine, that how the process could become a six sigma process? Simply by hypothetically understanding that if the standard deviation (sigma) is quite low like 1.5 minute. Then we can make almost 6 interval distance on the graph on the right side of the perpendicular mean line.

This way all the data would have been within those 6 standard deviation intervals which is total is 10 Minutes. This makes it a Six Sigma process. However, if the data only falls within the 3 standard deviations, it will mean the process is only 3 sigma, if the data falls within the 4 sigma intervals then that means the process is 4 sigma process, and so on.

This was the graphical representation of the Six Sigma process and how Six Sigma is applied to the process performance.

There is another simple formula to apply to determine the process sigma level. This is called the Z score. Once you have the customers’ specifications, the Upper Limit Specifications (USL) and the Lower Limit Specifications (LSL), you can derive out the customers’ Tolerance Level. As in this particular pizza delivery case, only the upper specification is relevant i.e. 40 minutes, Tolerance divided by the standard deviation gives you the sigma level.

In this case, SL - Mean / 10 = 40-30 = 10/10 = 1 Sigma. We can say that the process is 1 sigma level (not upto the 6 Sigma). This is the lowest which only produces about 31% yield and 69% defect rate. Huge.

Six Sigma DMAIC

Now when you have understood the basic overview of Six Sigma, let’s get into the Six Sigma DMAIC framework.

Define – Six Sigma DMAIC Stage 1

This is the first and the most important stage of Six Sigma DMAIC. If you go wrong here, you will waste efforts, money and time and nothing worthwhile will come out of it.

So take good care. Even if you have to spend more time here, do so, since it will matter for the success or failure of the project.

Every six sigma has to start first with a problem. Naturally, if there is no problem, then there is no project, and why should there be any project. So if nothing broken you don’t need to fix it. Finding the right problem is an expertise as well as an art.

The management has to provide the inputs, the bottom line inputs are also needed and then you have to identity the work area which is causing some problems like low sales, less profits, customer dissatisfaction, low productivity, low staff morale, defective items, duplicate work etc. There has to be something which should require some attention and solution. So find it hard and spend good time on it in close collaboration with the management staff.

Once you are able to find the problem, now you have to develop a project out of it. The first important step is to develop a project charter.

In this case, you have to first form a team who should be working on the project. And this team’s head should be the Project Champion the person who actually initiates the Six Sigma project. This six sigma team can include staff from the company as well as from outside the company. All staff members should have defined job tasks and responsibility and accountability. The project should have the start date and the end date.

The Six Sigma project should have clear problem statement and the objective statement to work on it.

Once this project charter is ready, it has to be signed off by the top management to kick start the Six Sigma DMAIC project.

Measure – Six Sigma DMAIC Stage 2

This is the second stage of Six Sigma DMAIC. It involves extensive data gathering and heavy data measurement.

Now as you are clear about the problem within a company, you have to dig in the past and get the required data.

Suppose, if it is a problem about the low staff productivity, you have to study the past 1-3 years’ data from the different work areas or the pinpointed work areas. This data may include the process outputs, the staff attendances, absenteeism, meetings, break times etc.

Once you start getting the required data, now you have to use the statistical tools to chart the data and see the trends. You should be clear what you are aiming at. In this case you need to find he reasons for low staff productivity.

During this stage, maximum possible data sample should be derived and tabulated and represented through various graphs and charts.

During the ‘Measure’ stage of Six Sigma DMAIC, after having taken all the required data, calculate the first level basic descriptive statistics that includes mean, median mode and standard deviation.

Analyze – Six Sigma DMAIC Stage 3

During the ‘Analyze’ stage, now you have all the data and you need to analyze it to find out the reasons behind the low staff productivity.

In this stage, you can use other statistical tools like scatter diagram, six sigma breakthrough equation and the correlation for the root cause analysis.

These are the three basic analysis tools for root cause finding. Interestingly, in many six sigma projects, these three can even provide us enough insight to move closer to the root cause analysis.

Especially the Scatter Diagram which is also called by two other names i.e. Fish Bone Diagram and Ishikawa Diagram. Ishikawa was the one who developed the Fishbone diagram concept.

According to it, you can use the head of the fish showing the effects or the problematic outputs. You can use the body of the fish to show the causes which may contribute to those undesired effects.

These causes can be further categorized as machine related, material related, people related, and environment related and you can even make more categories. This tool is a mixture of brainstorming as well as based on some previous hard data.

This stage is the most important stage in the Six Sigma DMAIC framework. This stage if done well starts providing you the clarity to see the patterns which can lead you to provide you the answers to your questions, like what is the cause behind the low staff productivity. And here you may have many revelations. The normally perceived reason may not be true.

Suppose the staff absenteeism is perceived as the reason for the low staff productivity, whereas this ‘Analysis’ stage may determine that the ‘process dependency on other process’ is actually the root cause of the staff low productivity which results in less output.

In this stage, you can play with the data with many manipulations, using many other advance statistical tools to ensure that you are arriving at the right root causes of the problems.

Improve – Six Sigma DMAIC Stage 4

Once you have pinpointed and determined the root causes, now is the time, to eliminate and improve the process to achieve the better productivity.

In this stage, you can now develop different modified processes to see what will be the effects.

You can either eliminate or reduce dependency on the other process, and provide more empowerment to staff to take the decisions, that can result in better process output.

With new process scenarios, you can use more advance level six sigma statistical tools here like Failure Mode Effects Analysis (FMEA) and Design for Six Sigma (DFSS).

Such tools can provide you more confidence and structure to improve with solid and confident solution.

After making all the improvements in the process, now you have to get the approval of the new process and implement it for the respective work areas.

A detailed communications plan also have to be developed so that all the staff within the company should be well aware of the new procedures in place.

Control – Six Sigma DMAIC Stage 5

After completing all the Six Sigma DMAIC steps, you now have to control the new process in order to ensure that it does not revert back to the old.

It also happens that when you don’t control it in a systematic and structured manner, any new change brought in may have the tendency to move back to the old ways just like a rubber band. That is the reason the ‘Control’ stage plays a very important role in Six Sigma DMAIC framework.

At this stage, there should be some dedicated staff assigned to monitor the progress of the new changes.

It can either be done with some automation or else some executive dashboard can be developed that will take inputs from all the concerned areas and will provide the overall picture of the process conformances and the non-conformances for the management.

Without such control activity, staff and the management can easily loose the track of the new status quo.

Many companies have lost lot of effort and money after the successful implementation of the Six Sigma DMAIC but failing to meet the requirements for the ‘Control’ stage, where they could not do full justice and the new processes gradually moved back to the old way of doing things.

Summing Up – Six Sigma DMAIC Framework

Six Sigma DMAIC framework is the backbone of the Six Sigma. Once you understand all the DMAIC steps or stages, you would almost master the Six Sigma implementation.

Although it may easier said than done, but it is the starting point, where you have to know what it takes to implement the six sigma project in any company.

You can also read an article at ASQ

Interestingly, the Six Sigma DMAIC framework is not only limited to business domain. You can also use the Six Sigma DMAIC framework even in your personal lives like career planning, health & fitness as well as relationships and other life issues.

The core spirit and philosophy of Six Sigma is that it is an improvement science based on the hard and some soft data.

It helps to eliminate or reduce the factors of ‘intuition’ and ‘gut feel’ based decisions and solutions. It provides you the clear confident direction and solution about what should work better, and avoiding what did not work earlier.

Six Sigma has achieved many milestones in the corporate sector that includes manufacturing and the service sector. Now it can even play its similar role in other areas of life as well.

Image Credits: All images provided by Pexel.com